In the material selection process of industrial pipelines and municipal engineering, the corrosion resistance of pipelines is a key consideration. As a common plastic pipeline material, whether PE pipes are resistant to acid and alkali corrosion has become the focus of many users. The answer is that PE pipes have good acid and alkali corrosion resistance and can withstand the erosion of common acid and alkali substances, but there are also limitations in use under specific working conditions.

PE pipes are made of polyethylene materials, and the polyethylene molecular structure is stable and the chemical properties are inert, which makes it able to maintain good chemical stability in the face of common acid and alkali solutions such as dilute hydrochloric acid, dilute sulfuric acid, and sodium hydroxide solutions. In general industrial drainage, sewage treatment, and municipal water supply projects, PE pipes can stably transport liquids containing acid and alkali components for a long time, and are not easy to be damaged by corrosion. Its corrosion resistance not only prolongs the service life of the pipeline, but also reduces the maintenance cost, so it is widely used in civil and general industrial fields.

However, the corrosion resistance of PE pipes is not unlimited. In the chemical industry, high temperature and high concentration of acid and alkali environment have extremely high requirements for pipeline materials, and PE pipes are difficult to meet such harsh conditions. Excessive temperature will accelerate the molecular chain fracture of PE materials, while high concentration of strong acid and alkali may break through its chemical inertness, resulting in swelling, brittleness and even damage of the pipeline. Therefore, in the chemical industry, the transportation of acidic media is usually made of fiberglass reinforced plastic pipes, whose multi-layer composite structure can effectively resist strong acidic substances; the transportation of alkaline media is commonly used in PPH pipes, which are excellent in alkali resistance.

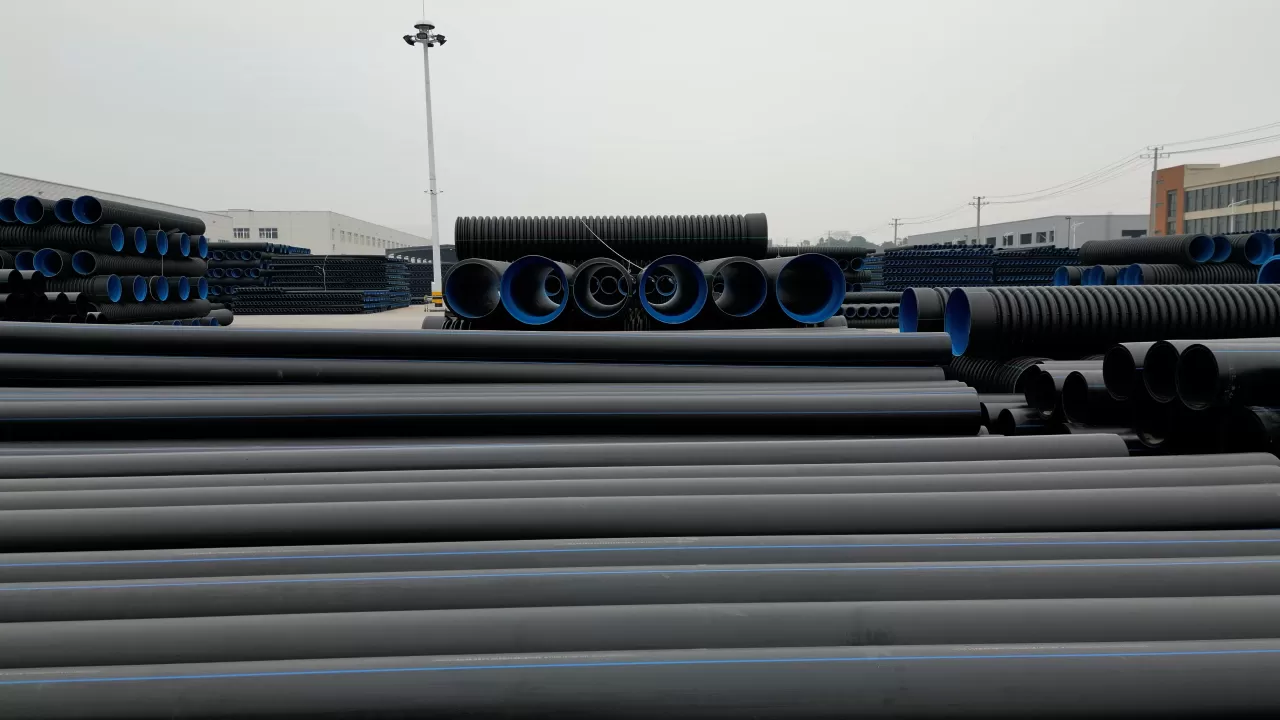

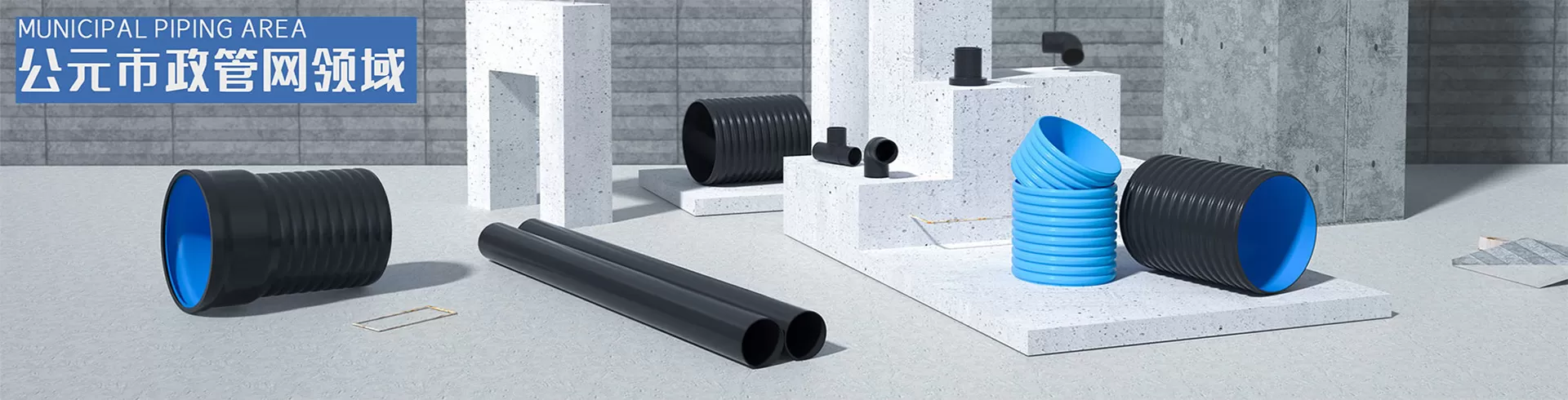

in the PE pipe market, Hubei AD PE Building Materials Co., Ltd. stands out as a professional PE pipe manufacturer. As a representative enterprise of Hubei PE pipe manufacturers, its production of AD PE pipes covers a variety of specifications such as large diameter, and the product quality strictly follows national standards. From raw material procurement to production process, to finished product testing, every link is strictly controlled to ensure that AD PE pipes meet the industry's leading level in corrosion resistance and compression resistance. Whether it is ordinary industrial applications or municipal engineering construction, AD PE pipes can provide reliable protection for projects with stable performance.

If you are looking for high-quality PE pipe products, or have further consultation needs on the acid and alkali resistance of the pipeline, please call Hubei AD Building Materials Co., Ltd. 17399989993. The professional technical team will provide detailed product solutions and technical support according to your actual needs, so that you have no worries about the selection of pipeline materials.