First, perforated osmosis pipe, rainwater osmosis pipe introduction:

rainwater perforated osmosis pipe is based on the traditional rainwater discharge, the rainwater pipe or open channel into the osmosis pipe (perforated pipe), the surrounding backfill gravel, rainwater through buried in the underground porous pipe to the surrounding soil layer. By replacing some of the pipes in the community with osmosis pipes, rainwater can first penetrate below the ground to replenish groundwater, and at the same time reduce the drainage pressure of municipal pipes, thereby avoiding water accumulation on the ground.

Second, perforated osmosis pipe product features:

1, small footprint, easy to set up in urban areas and living quarters, it can be used in combination with rain water pipe system, osmosis pool, osmosis well, etc., or can be used alone.

2, high water permeability efficiency, can be directly buried in the soil, complete the penetration of rainwater, avoid excessive water on the ground, affect the environment.

3, good corrosion resistance, high strength, small internal resistance, tensile and bending resistance.

4, long life, good toughness, pipeline does not break.

III. Application of perforated permeable pipe:

Rainwater perforated permeable pipe is used in the rainwater infiltration of residential areas, parks, roads, playgrounds, golf courses, schools, etc.

1, perforated permeable pipe construction process

Measurement of release line 1 + excavation trench 1 + laying sand 1 > laying geotextile 1 + laying bottom gravel 1 + installing permeation facilities 1 + laying side gravel 1 + wrapping geotextile 1 + backfilling.

2, construction method

2. 1.1

Measurement of pay-off Use a total station instrument to measure the center line of the infiltration facility, calculate the groove size according to the size of the infiltration facility and the structure of the surrounding facilities, and sprinkle the slotted edge of the infiltration facility with white ash to make excavation. 1.2

Excavation of trenches The trenches are manually excavated, and the trench walls are vertical and do not slope. The plane size of the trenches shall not be less than the outer size of the structure of the infiltration facility. Protect the trench walls after the excavation is completed. With the excavation, the elevation of the bottom of the trench is measured to prevent overexcavation from destroying the original soil. The elevation deviation of the bottom of the trench is 20mm.

2. 3

The sand used in laying medium sand must be qualified, the mud content of the sand is 3%, the sand should be tested after entering the field, and its quality should comply with the relevant national regulations. The medium sand is laid manually, and the workers use a shovel for preliminary leveling, and then use a flat plate vibration compaction to level and compact, the permeability coefficient is 1x104m/s.

3. 1

Laying geotextile According to the size of the groove and the lap length, determine the size of the geotextile, and then cut the geotextile. The geotextile should be laid flat, and the longitudinal lap length is 500mrmlp to open the upper mouth of the geotextile. After the gravel laying is completed, the upper mouth of the geotextile is closed and lapped.

3. 2

Lay the crushed stone at the bottom. The particle size of the crushed stone laid at the bottom is 20-30 mm, and the porosity is 39%. The crushed stone is required to be clean and the surface of the crushed stone is flat. The crushed stone should be sieved before use to increase the permeability of the crushed stone. After the laying is completed, it should be reviewed whether the bottom elevation conforms to the design elevation. When the crushed stone is laid, a certain amount of settlement should be pre-packed, and the data of the settlement amount should be determined by the test section.

3. 3

The landfill crushed stone and geotextile crushed stone should be backfilled. The crushed stone should be filled below the water surface, and the crushed stone should be compacted by flat plate vibration, and the surface of the crushed stone should be leveled, and then the geotextile should be tightened.

4. 1

After the acceptance of the hidden engineering of the backfill soil pipeline, cover the geotextile with soil. The water content of the fill should be close to the optimal water content. Fillers shall not contain organic impurities, and shall not use silt or muddy soil as backfill materials. Before backfilling, the broken bricks, stones and hard soil blocks greater than 10c contained in the soil should be screened off. The backfill thickness of each layer of fill should not exceed 200mm. Fillers should use impact vibration compaction to lay down the fill in layers. The compaction should be compacted and connected to ensure that there is no leakage compaction. At the lap of two backfill sections that are not carried out at the same time, the compaction layer will be compacted into a stepped shape with the laying of soil, and the length of the step is greater than 2 times the height. The compaction height of the fill above the top of the tube is more than 500ml, and a road roller can be used.

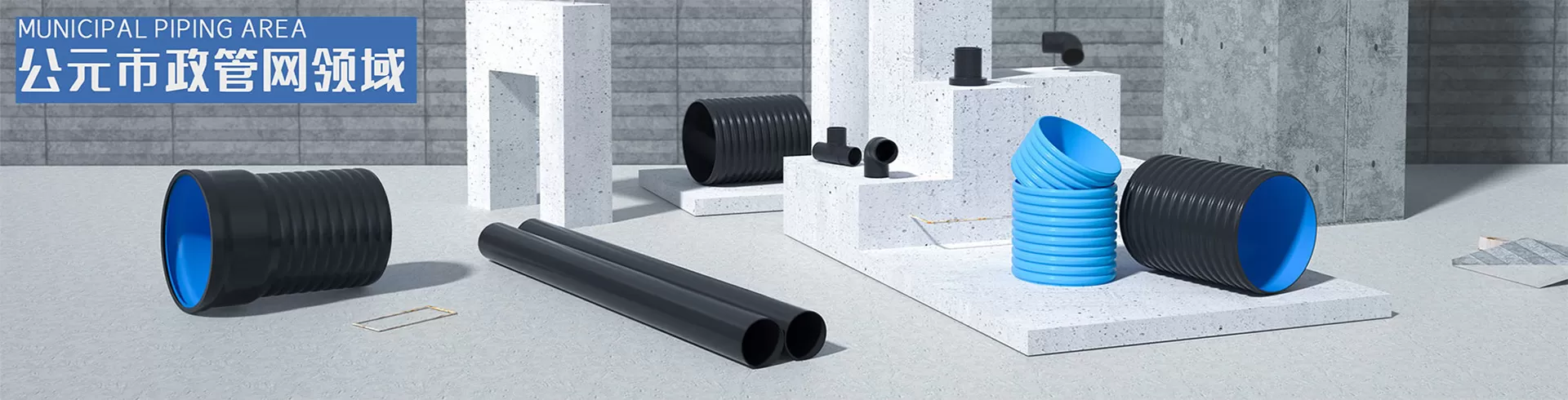

can be used for seepage pipeline products are: HDPE double-wall corrugated pipe, winding pipe; PE solid wall pipe, PVC, the water permeability can reach 50%, the specific parameters are as follows:

Specification length (mm) 360 integral punching

several equal parts

aperture (mm) hole distance (mm) 50600441075600441090600651011060068101256006101516060061215180600614152006008141522560081615250600101615280600101615315600102015355600122015400600122015 perforated permeable pipe generally used PE pipe punching as permeable pipe, also used PE double-wall corrugated pipe, Pvc double-wall corrugated pipe, PVC solid wall pipe punching, we can choose according to their needs, Hubei PE perforated pipe manufacturers, Wuhan PE perforated pipe manufacturers are Hubei AD Building Materials Co., Ltd.

Source: Hubei AD Building Materials Co., Ltd., welcome to share! Hotline: 17399989993