As a lightweight and corrosion-resistant plastic pipe,

PE pipe is widely used in household water supply pipes, municipal threading pipes, small drainage systems and other scenes. Many people will ask when DIY maintenance or small project construction: Can PE pipe be welded with a plastic welding torch? In fact, there is no absolute answer to this question - whether the plastic welding torch can weld PE pipe depends on the pipe diameter, wall thickness, and your requirements for welding quality.

First clarify two basic concepts: the conventional welding logic of PE pipe, and the working principle of plastic welding torch.

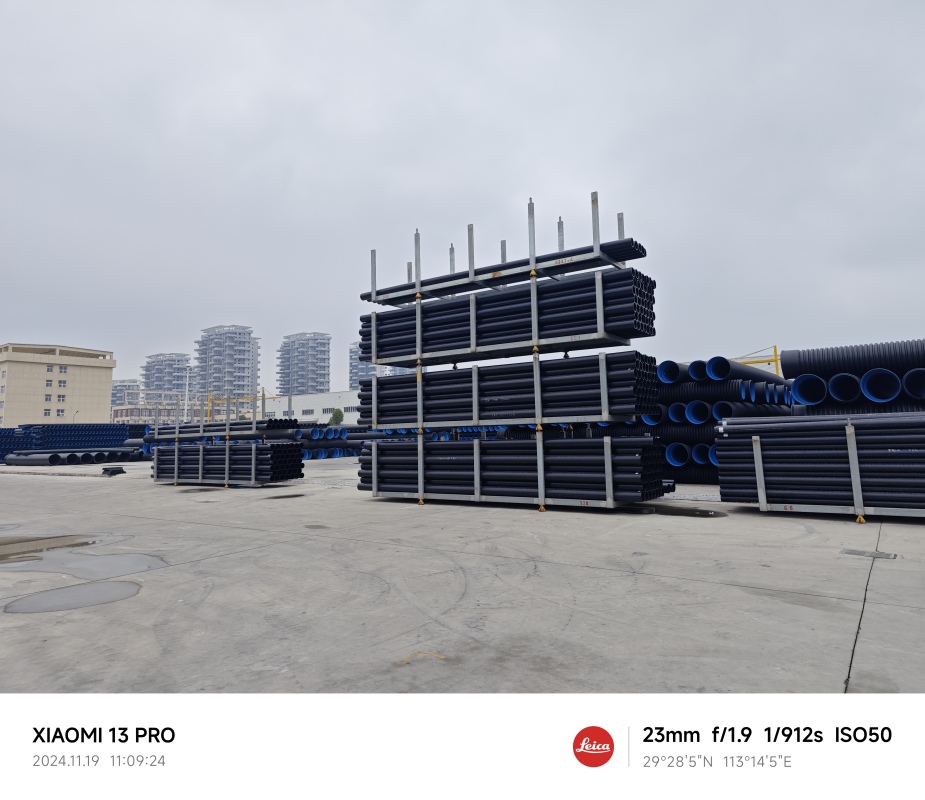

PE pipe "standard welding method" is actually hot melt butt and electric fusion welding. Hot-melt docking is to heat and melt the end faces of two PE pipes and then directly connect them. The interface is fused by pressure, which is suitable for large-diameter (above DN100) and thick-walled PE pipes (such as municipal drainage pipes); electrofusion welding is to use electrofusion pipe fittings (with resistance wires inside) to heat up, so that the pipe fittings and pipes are fused into one, suitable for complex interfaces or small space construction. The core of these two methods is "sufficient heat + uniform pressure", which can ensure the strength and sealing of the interface and meet engineering standards.

The principle of a plastic welding torch (also known as a hot air welding torch) is simpler: blow high-temperature hot air through the heating element in the gun, melt the surface of the plastic pipe and the supporting welding rod (such as PE welding rod) at the same time, and then fill the interface with the welding rod, and form a connection after cooling. The advantage of this method is that it is flexible in operation and portable in tools. It is often used for small-scale repair of plastics such as PVC and PP, but can it be used for PE pipes? It depends on the scene.

The case where the plastic welding torch can weld PE pipes: small diameter, thin-walled pipe

If it is a small-diameter (DN20-DN63), thin-walled (wall thickness 3mm) PE pipe, such as a household water supply pipe (DN25), an electrical threading pipe (DN32), a plastic welding torch can be used. This type of pipe itself is thin in wall thickness and requires little heat. The hot air of the plastic welding torch can quickly melt the pipe surface and electrode, and it is also flexible to operate - such as repairing a small crack or connecting a short pipe. The plastic welding torch is more convenient than the hot melt machine.

For example: the PE water supply pipe at home is accidentally smashed with a small crack. Use the plastic welding torch to add the PE welding rod, heat and melt around the crack, and then fill it with the welding rod. It can be repaired after cooling, and it will not affect daily use.

Plastic welding torches cannot weld PE pipes: large-diameter, thick-walled pipes

But if it is a large-diameter (DN100 or more), thick-walled (5mm wall thickness) PE pipe, such as the drain pipe of the municipal main road and the gas transmission pipe for industrial use, the plastic welding torch is "powerless". The reason is very simple: the heat required for thick-walled PE pipes is several times that of small-diameter pipes. The hot air of the plastic welding torch can only heat the surface of the pipe, and the entire wall thickness cannot be uniformly melted. The surface looks welded, but the interior is not actually fused. Once the water pressure or air pressure is flushed, water and air leakage will occur, which completely fails to meet the engineering requirements.

4 key precautions for welding PE pipe with plastic welding torch

Even if it is a small diameter PE pipe, welding with plastic welding torch must pay attention to the following points, otherwise it is easy to cause problems:

1. Temperature should be accurate: The melting point of PE pipe is around 120-130 ° C, but the hot air temperature of plastic welding torch should be adjusted to 300-400 ° C (because hot air contact with air will cool down). If the temperature is too high, the PE pipe will burn through and carbonize; if it is too low, it will not melt and the interface is not firm.

2. Welding electrodes should be "matched": PE electrodes of the same material must be used! Can not be replaced by PVC or PP electrodes - different plastics have different melting points and compatibility, and using the wrong electrode will cause cracking of the interface.

3. The operation should be uniform speed: The welding torch should move slowly along the interface, so that the hot air can evenly heat the pipe surface and the welding rod to avoid local overheating. When filling the welding rod, it should be "stable", and do not let the welding rod be wrapped in air (it will form bubbles and affect the sealing).

4. The environment should be protected from wind and rain: The strong wind will blow the heat dissipation air, resulting in uneven heating; the low temperature (below 5 ° C) will make the molten plastic cool quickly, and the interface is prone to brittle cracking. It is best to operate indoors or in a windless environment.

Summary: The plastic welding torch is a "supplementary tool", not a "universal welding tool."

Back to the original question: Can the PE pipe be welded with plastic torch? The answer is - small-diameter thin-walled pipes can be used, and large-diameter thick-walled The value of plastic welding torches lies in "flexible repair", not "replacement of standard welding methods". If you want to do minor home repairs and small-scale renovations, plastic welding torches are a good choice; but if it is an engineering-grade PE pipe installation (such as the community water supply pipe network), you still have to honestly use hot melt or electric fusion welding. After all, this is a "regular operation" that can guarantee a 50-year service life.

Finally, a reminder: No matter what method is used to weld PE pipes, you must do a pressure test after welding - use a pressure test pump to pressurize the pipe (usually 1.5 times the working pressure) and keep it free of water leakage for 30 minutes to be qualified. After all, the core requirement of PE pipes is "no water leakage". Don't ignore the most critical quality inspection because of the convenience of the picture. SEO keywords: [PE pipe can use plastic welding torch, PE pipe welding method, plastic welding torch welding PE pipe, PE pipe hot air welding

First clarify two basic concepts: the conventional welding logic of PE pipe, and the working principle of plastic welding torch. The "standard welding method" of

PE pipe is actually hot melt butt and electric fusion welding. Hot melt butt is to heat and melt the end faces of two PE pipes and then directly connect them. The interface is fused by pressure, which is suitable for large diameter (above DN100) and thick wall PE pipes (such as municipal drainage pipes); electric fusion welding is to use electric fusion pipe fittings (with resistance wire inside) to heat up, so that the pipe fittings and pipes are fused into one, suitable for complex interfaces or small space construction. The core of these two methods is "sufficient heat + uniform pressure", which can ensure the strength and tightness of the interface and meet engineering standards.

The principle of a plastic welding torch (also known as a hot air welding torch) is simpler: high-temperature hot air is blown through the heating element in the gun, the surface of the plastic pipe and the matching welding rod (such as PE welding rod) are melted at the same time, and then the interface is filled with the welding rod, and the connection is formed after cooling. The advantage of this method is that it is flexible in operation and portable in tools. It is often used for small-scale repair of PVC, PP and other plastics, but can it be used for PE pipes? It depends on the scene.

Plastic welding torch can weld PE pipes: Small diameter, thin-walled pipe

If it is a small diameter (DN20-DN63), thin-walled (3mm wall thickness) PE pipe, such as household water supply pipe (DN25), electrical threading pipe (DN32), plastic welding torch can be used. This type of pipe itself has a thin wall thickness and does not require much heat. The hot air of the plastic welding torch can quickly melt the pipe surface and welding rod, and it is also flexible to operate. For example, repairing a small break or connecting a short pipe, plastic welding torch is more convenient than hot melt machine.

For example: A small crack was accidentally smashed in the PE water supply pipe at home. Use a plastic welding torch to add a PE welding rod, heat and melt around the crack, and then fill it with a welding rod. It can be repaired after cooling, and it will not affect daily use.

The case where the plastic welding torch cannot weld PE pipes: large diameter, thick wall pipe

But if it is a large diameter (DN100 or more), thick wall (wall thickness 5mm) PE pipe, such as the drain pipe of the main road of municipal government and the gas transmission pipe for industrial use, the plastic welding torch will be "powerless". The reason is very simple: thick-walled PE pipe requires several times the heat of small-diameter pipe, plastic welding torch hot air can only heat the surface of the pipe, can not make the entire wall thickness uniform melting - the surface looks welded, the inside is not actually integrated, water pressure or air pressure will leak, leakage, completely fail to meet the engineering requirements.

4 key considerations for welding PE pipe with plastic welding torch

Even if it is a small-diameter PE pipe, welding with plastic welding torch must pay attention to the following points, otherwise it is prone to problems:

1. Temperature should be accurate: the melting point of PE pipe is around 120-130 ° C, but the hot air temperature of plastic welding torch should be adjusted to 300-400 ° C (because hot air contact with air will cool down). If the temperature is too high, the PE pipe will burn through and carbonize; if it is too low, it will not melt and the interface will not be firm.

2. The electrode should be "matched": PE electrodes of the same material must be used! PVC or PP electrodes cannot be used instead - different plastics have different melting points and compatibility, and using the wrong electrode will cause cracking of the interface.

3. Operation should be uniform speed: The welding torch should move slowly along the interface, so that the hot air can evenly heat the pipe surface and electrode to avoid local overheating. When filling the electrode, it should be "stable", and do not let the electrode be wrapped in air (it will form bubbles and affect the sealing).

4. The environment should be protected from wind and rain: high winds will blow the heat dissipation wind, resulting in uneven heating; low temperatures (below 5 ° C) will make the molten plastic cool quickly, and the interface is prone to brittle cracking. It is best to operate indoors or in a windless environment.

Summary: Plastic welding torch is a "supplementary tool", not a "universal welding tool."

Back to the original question: Can plastic welding torch be used for PE pipe? The answer is - small diameter thin-walled pipe can be used, large diameter thick-walled pipe should not be used. The value of plastic welding torch lies in "flexible repair", not "replacement of standard welding method". If you want to do a small home repair, small-scale renovation, plastic welding torch is a good choice; but if it is an engineering-grade PE pipe installation (such as community water supply pipe network), you still have to honestly use hot melt or electric fusion welding, after all, this is a 50-year service life can guarantee the "normal operation".

Finally, remind: no matter what method is used to weld PE pipe, you must do a pressure test after welding - use a pressure test pump to pressurize the pipe (usually 1.5 times the working pressure), keep it for 30 minutes without water leakage, it is qualified. After all, the core requirement of PE pipe is "no water leakage", don't ignore the most critical quality inspection because of the convenience of the picture.