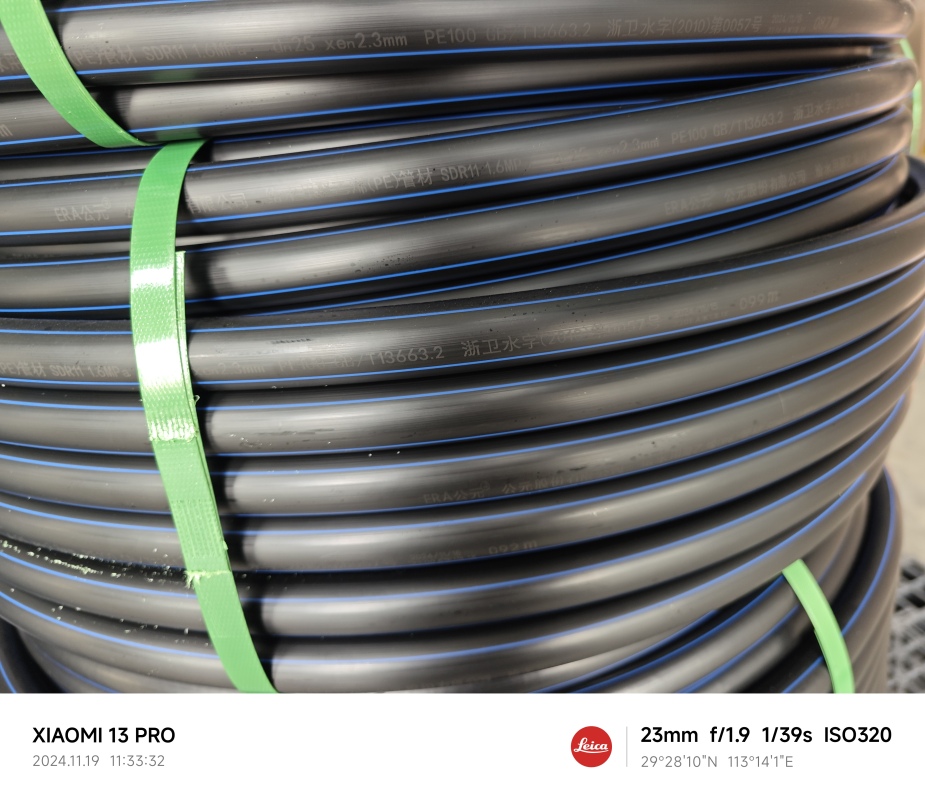

PE pipe, as a commonly used plastic pipe, can be bent and laid due to its outstanding flexibility. This characteristic makes it very advantageous in complex terrain or scenarios where obstacles need to be bypassed, which not only reduces the difficulty of construction, but also reduces the number of joints, and improves the integrity and sealing of the pipeline system. The flexibility of

PE pipe is due to its material characteristics - the main raw material is high density polyethylene (HDPE) or medium density polyethylene (MDPE). These polymers have good elastoplasticity: they can produce reversible deformation under the action of external force, and can be partially restored after the external force is withdrawn. Compared with rigid pipes such as steel pipes and PVC-U pipes, PE pipes can be adjusted without relying on a large number of elbows, which reduces the risk of leakage from the root cause, which is also the core reason why it is called "flexible pipe".

However, the bending of PE pipes is not "random", and the minimum bending radius is a key limitation. According to the conventional requirements of the industry, the minimum allowable bending radius of PE pipes is usually 15-20 times the pipe diameter (the specific wall thickness, pressure grade and manufacturer's technical description of the pipe shall prevail). For example, PE pipes with DN110 have a minimum bending radius of about 1.65-2 meters; PE pipes with DN200 require 3-4 meters. If the bending radius is too small, the pipe will be permanently deformed due to stress concentration and even cracked, which will seriously affect the service life.

There are still a few points to be paid attention to in the construction:

The first is temperature control - the flexibility of PE pipe is obviously affected by temperature: at low temperature (-5 ° C), the material brittleness increases, and it is easy to crack when forced to bend; at high temperature (40 ° C), the pipe softens, and it is difficult to maintain its shape after bending. Therefore, it is necessary to avoid extreme temperature construction, or take thermal insulation (such as covering thermal insulation cotton) and cooling (such as water spraying) measures.

The second is the bending method - small diameter (DN110) PE pipe can be artificially cold bent, but it needs to be applied slowly to avoid uneven local force; large diameter pipe is recommended to use a special pipe bender, or use the hot bending method (heated to 120-150 ° C, slowly bent and naturally cooled and shaped).

the last is to avoid repeated bending - repeated bending will lead to pipe fatigue, reduce strength, construction should be formed as much as possible.

It is this "bendable" characteristic that makes PE pipes "like a duck to water" in multiple scenarios:

- Rural water supply and drainage: bypass terrain obstacles such as ridges and ditches to reduce earthwork excavation;

- Gas pipelines: bypass buildings and green belts in the community to reduce damage to the existing environment;

- Municipal transformation: through non-excavation technology (such as directional drilling) bending and laying, no need for large-scale road breaking;

- Water conservancy projects: along rivers, hillsides and other complex terrain laying, adapt to natural landforms.

summary, PE pipes can be bent and laid, but the principle of "reasonable bending radius + correct construction method" needs to be followed. This characteristic not only improves the construction efficiency, but also strengthens the reliability of the pipeline by reducing the joints, which is an important advantage of PE pipes in many fields. In practical applications, only by combining the pipe parameters, environmental conditions and specification requirements can it give full play to its "flexible" value.